The cleaning of air inlet trellis with SpeedMaster SR protects the surfaces of the trellis effectively removing dirt and calcification

PVC air intake trellis are used worldwide in heat exchangers, e.g. in cooling towers. Especially with suction-ventilated units, they filter out coarse contamination. The air intake trellis are also impermeable to water and sunlight and reduce algae growth.

However, calcification can occur on the surfaces of the air inlet trellis. The calcification hardens over time to limestone if not regularly removed. Such limestone can no longer be removed mechanically from the thin, delicate surfaces without damaging the trellis. Kipp Umwelttechnik therefore recommends regular cleaning before the calcification hardens too much. With preventative cleaning, the trellis can be cleaned in-situ. For this, Kipp Umwelttechnik has developed a special process together with its sister company mycon GmbH: SpeedMaster SR. It provides efficient cleaning power at pressures from 2 bar without damaging the sensitive plastic surfaces. Also, the galvanized frame profiles are not affected.

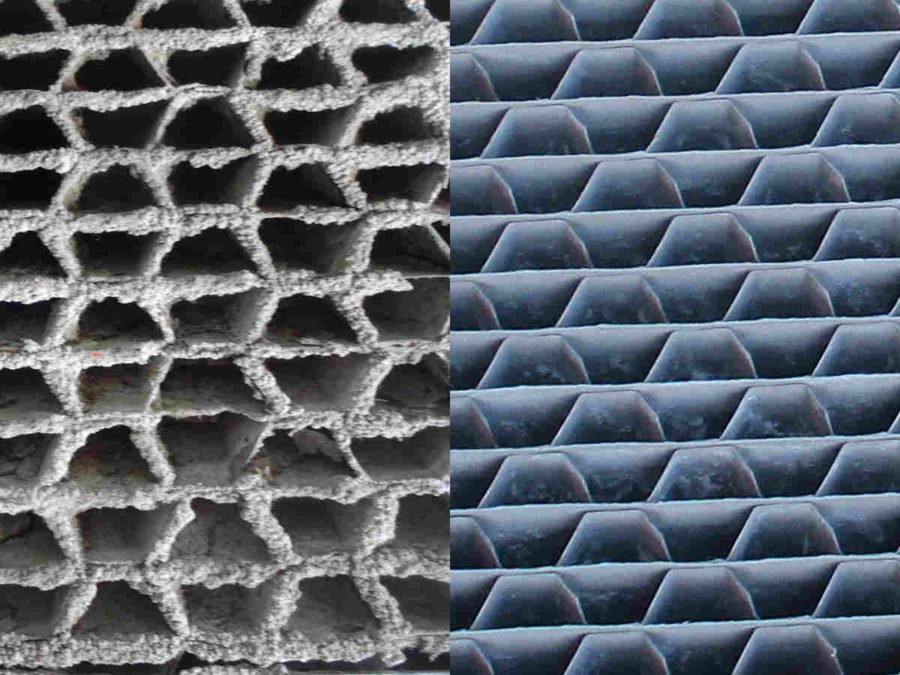

Air intake trellis before and after cleaning

But even with existing strong calcification Kipp Umwelttechnik can achieve very good cleaning results without damaging the air inlet mesh. However, the trellis must be removed before. The cleaning then takes place at Kipp Umwelttechnik in several steps using SpeedMaster SR and a combination of devices. For the cleaning of strong calcification a total of four steps are required. Nevertheless, the cleaning is worthwhile compared to the cost of replacement.

Cleaning air intake trellis using SpeedMaster SR

SpeedMaster SR offers versatile applications

Air intake trellis cleaning is just one of many uses for SpeedMaster SR. The process can be used in a variety of ways, for example also for removing thick, highly viscous grease deposits. Even painted surfaces remain undamaged when cleaned with SpeedMaster SR.

Removal of highly viscous grease deposits from painted surface using SpeedMaster SR

Also, the cleaning of bogies from the railway sector is an application for the SpeedMaster SR process.

Environmental compatibility of the SpeedMaster SR

Environmental friendliness was also taken into account during the development of the process. The cleaning medium used in SpeedMaster SR can be separated and re-used.